Rolling Coil, Rolling Sheet, Rolling Foil

The mass production of rolling coils or rolling sheets ensuring their high purity and quality.

Ti Substrate

The physical property of titanium ( Ti ) are as below:

High melting point: 1,668℃( above the ones of Fe )

Light weight ( approx. 60% of Fe, 1.7 of Al )

Low coefficient of thermal expansion (approx.half of stainless steel, 1/3 of aluminium )

Low coefficient of heat conduction: 0.041cal/c㎡/sec/℃/cm ( the same as stainless steel 18-8 )

High resistivity: 55μΩ-cm (higher resistivity compared with pure metals excluding stainless steel 18-8 )

Magnetic permeability 1.0001 is nonmagnetic material.

Below transformation point of crystalollne structure ( 885℃ ) is closed-packed hexagonal system. Above it is body-centered cubic structure.

Low modulus of longitudinal elasticity: 10,850kg/mm2 (approx. half of Fe, 1.5 of Al.

Stainless substrate

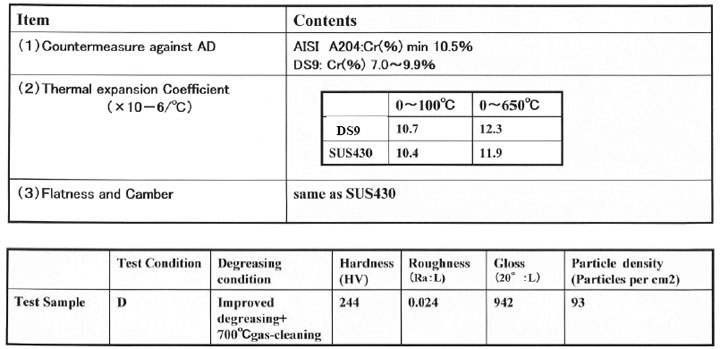

Improved material for solar cell (DS9 Coil trial samples):

Chemical Composition | |

SUS430 | DS9 |

C: 0.12max | C: 0.02max(0.006) |

Si: 0.75max | Si: 0.5max(0.2) |

Mn: 1.00max | Mn: 0.5max(0.2) |

P: 0.040max | P: 0.04max(0.025) |

S: 0.030max | S: 0.03max(0.005) |

Ni: 0.60max | Cr: 7.0 ~ 9.9(9.4) |

Cr: 16.00 ~ 18.00 | Cu: 1.0max(0.4) |

PI substratePI characteristics outstanding mechanical characteristics high tensile strength and modulus Electrical characteristics Thermal property Low heating shrinkage rate and high dimension stability

| |

|

PI Thermal expansion coefficient change

The coefficient of thermal expansion of PI is close to the ones of Si thin film solar battery and CIGS solar battery. Other thermal expansivities can be also developed according to customers’ requirements.

The possibility of operability and product features compatibility is improved because of the compatibility between the thickness and low thermal expansion coefficients.

Properties | Test Items | Units | NT-025 | NT-050 | NT-075 | Test Condition | Test Method |

Mechanical | Thickness | μm | 25 | 50 | 75 | - | - |

Tensile Strength | Kgf/mm2 | 28 | 28 | 25 | 20℃ | ASTM D882 | |

Elongation | % | 80 | 80 | 80 | 20℃ | ASTM D882 | |

Young's Modulus | Kgf/mm2 | 340 | 340 | 320 | 20℃ | ASTM D882 | |

Electrical | Dielectric Breakdown Voltage | KV/mil | 5.8 | 3.4 | 2.5 | 60Hz, 20℃ | ASTM D149 |

Dielectric Constant | - | 3.2 | 3.2 | 3.2 | 1MHz, 20℃ | ASTM D150 | |

Dissipation Factor | - | 0.007 | 0.007 | 0.007 | 1MHz, 20℃ | ASTM D150 | |

Volume Resistivity | Ω?cm | >1016 | >1016 | >1016 | 500V, 20℃ | ASTM D257 | |

Surface Resistance | Ω | >1016 | >1016 | >1016 | 500V, 20℃ | ASTM D257 | |

Thermal | Coefficient of Thermal Expansion | ppm/℃ | <35 | <35 | <35 | 100~200℃ | ASTM D696 |

Heat Shrinkage | % | <0.05 | <0.05 | <0.05 | 200℃, 2hr | ASTM D5213-04 | |

Glass Transition Temperature(Tg) | ℃ | >380 | >380 | >380 | - | DMA TMT Method | |

Physical | Moisture Absorption | % | 2.5 | 2.5 | 2.5 | 20℃, 24hr Immersion | ASTM D570 |

Density | g/cc | 1.46 | 1.46 | 1.46 | 20℃ | ASTM D1505 | |

Chemical | MEK丁 | Tensile Strength MD Retained % | 100 | 100 | 100 | 20℃, 10 min Immersion, then test after 24 hrs. | ASTM D882 |

Benzene | 100 | 100 | 100 | ||||

Toluene | 100 | 100 | 100 | ||||

Methanol | 100 | 100 | 100 | ||||

Acetone | 96 | 96 | 96 | ||||

10%HCl | 96 | 96 | 96 | ||||

10%H2SO4 | 98 | 98 | 98 | ||||

5%NaOH | 85 | 85 | 85 | ||||

FeCl3 | 94 | 94 | 94 | ||||

CuCl2 | 79 | 79 | 79 |

Any interest, please leave your contact info. We will feedback ASAP.

NEXTECK is committed to solar photovoltaic supply for many years. We have established long-term cooperative relations with many well-known solar PV manufacturers. Our products are exported to many countries in Europe and Southeast Asia . NEXTECK provides safe and convenient PV connectors which are certified by German TUV .